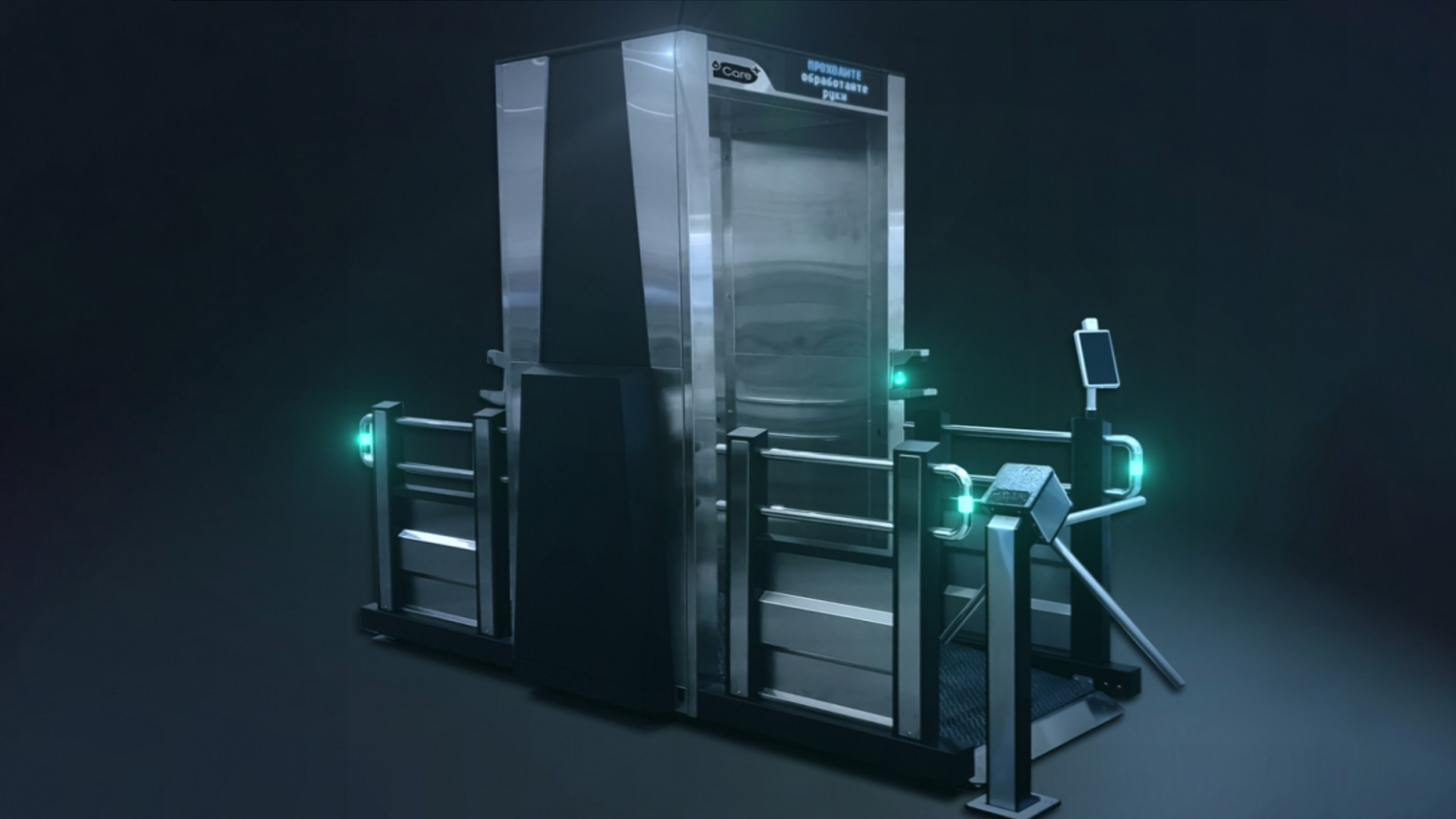

NCare Booth

The stainless steel frame is used in an assertive environment. It includes convenient and simple functions, quality material inputs, sustainability of work and simple service..

Get it Now!

Automatic Non-Contact hand sanitizer

Antiseptic is installed on the struts of a basic module. It has a built-in contactless infrared sensor which is triggered at a distance from 5 to 15 cm and 800 ml container with sanitizer.

Get it Now!

High traffic flow thermographic camera

A traffic camera is installed on the struts of the basic module with face detection function of contactless temperature measuring. It allows to control the body temperature of passing people..

Get it Now!

User-friendly

The disinfectant rug is for the treatment of shoe soles at the bottom of the frame. Mud-resistant grids and ramps for persons with special needs can be fitted at the entrance and exit (Optional).

Get it Now!